Impact of Artificial Intelligence in Manufacturing Industry

Free Machine Learning courses with 130+ real-time projects Start Now!!

In this Artificial Intelligence Tutorial by DataFlair, we will learn the impact of Artificial Intelligence in Manufacturing Industry along with its future.

Artificial Intelligence in Manufacturing Industry

The manufacturing sector can profit by utilizing digital physical frameworks so as to make creation lines increasingly productive. The Fourth Industrial Revolution, based on the foundation of knowledge-based work, obtained by mechanization; by making better approaches to computerize processes.

We can reconstruct the manner in which individuals and machines live, connect and team up, to make an unrivaled, more robust, and self-learning production lines with minimum idle time.

The major breakthrough in manufacturing has been the introduction of assembly lines to achieve economies of scale. In this decade, AI has all the potential to be the disrupter.

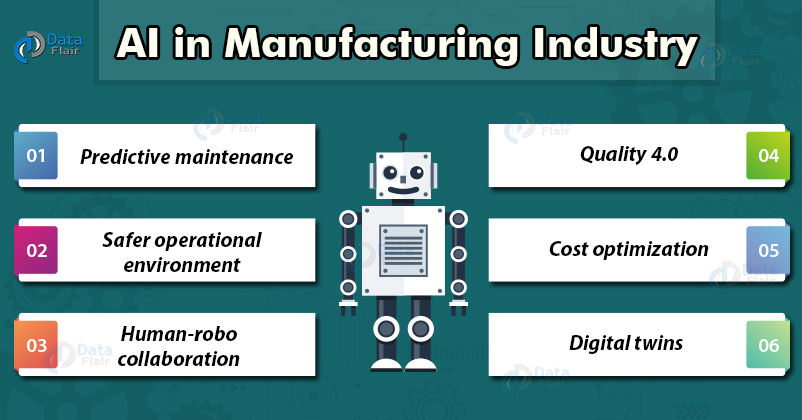

So, let us take a look at how AI can revolutionize manufacturing sector:

1. Predictive Maintenance

Throughout the years, the assembling business has been utilizing receptive support methodology to fix machine parts after they come up short.

From that point forward, the industry moved to preventive support where the machine upkeep is done according to the arranged calendar made while thinking about its past disappointments.

With the approach of man-made consciousness, producers are ready to dispose of machine disappointments utilizing prescient upkeep.

Technology is evolving rapidly!

Stay updated with DataFlair on WhatsApp!!

For example, a machine is under continuous load. Here, with the help of an infrared imager, we can monitor the temperature profile of equipment without affecting the overall performance.

In prescient upkeep, the advantage usage information can be taken care of into the AI models, which will at that point foresee the hour of potential segment disappointments. This methodology will fix the issue before it happens, along these lines making a continuous creative process.

The prescient support approach works better than receptive and preventive upkeep as it deals with expanding resource life and use. Moreover, the gear or segments are adjusted just when they are going to fizzle. This ensures no cash is being spent on supplanting parts that work fine and dandy.

2. Safer Operational Environment

With even a minor mistake occurring on the assembly line proving hazardous, a stage towards AI implies less human assistance needed to complete perilous and relentless work.

As robots supplant people and perform typical and unsafe exercises, the number of working environment mishaps will diminish the whole way across. As a result, this will lead to safer working conditions than before.

For example, instead of a human doing a crash test of a car, an AI would be a natural option.

3. Human-Robo Collaboration

There are a large number of robots working in manufacturing plants everywhere throughout the world. People are concerned that their occupations may be supplanted by robots. Laborers do have restrictions and they can work in shifts. While robots are progressively gainful and can work 24*7.

Assembling units can be joined with robots. Individuals can be recruited for more elevated level situations for programming and the executives of the business forms.

As the appropriation of robots in the assembling business expands, organizations can concentrate on the business exercises and develop their deals and benefits.

Learn more about AI and Robotics.

4. Quality 4.0

A large portion of the producers thinks that it is hard to keep up quality reliably. Because of the rising multifaceted nature in the items and the extra parts, producers everywhere throughout the world may confront the test to keep up the top nature of products.

Utilizing industry 4.0 methods, they can deliver the great nature of items by utilizing AI calculations created through AI. If any issue is found at the starting stages, we can deal with it right away. Quality 4.0 guarantees the improved nature of items and the upgraded yield for producers.

5. Cost Optimization

Though it is imperative that bringing AI into the production lines would require an enormous capital venture, but the ROI is altogether high. As astute machines begin dealing with everyday exercises, organizations can appreciate lower working costs.

One of the significant advantages of AI and IoT in assembling is cost streamlining. Assembling organizations can utilize the accessible assets, machines, frameworks, and robots to infer the most extreme yields. Use of Sensors support profitability and proficiency and increase the greatest ROI.

6. Digital Twins

Lastly, The concept of AI and Digital Twins utilizes the advanced twin innovation to make a virtual portrayal that reproduces the physical attributes of the plant, items, or machine segments.

By utilizing cameras, sensors, and different strategies for information assortment, the computerized twin can mirror the continuous data relating to this present reality.

In less difficult words, an advanced twin can make a live model of the production line plant. Having a computerized model lets designs precisely foresee wear, development, and collaborations with different gadgets.

Future of AI in Manufacturing

Finally, manufacturing in the near future would be fully automated. The manufacturing processes enabled by Artificially Intelligent Systems would be able to perform the required processes. It will also be able to inspect, improve, and quality checks the products without any human intervention.

According to the reports of Marketsandmarkets, Artificial Intelligence in the manufacturing market is expected to grow from USD 1.0 billion in 2018 to USD 17.2 billion by 2025, at a CAGR of 49.5% during the forecast period.

Summary

In conclusion, we have seen how Artificial Intelligence in manufacturing is impacting the world. But contrary to the threat of human positions losing to AI, the assembling would proceed towards higher profitability and expanded effectiveness with the assistance of AI.

Subsequently, the workforce can concentrate more on advancement and new tasks. They can finally add more to the development and splendid eventual fate of the Manufacturing Industry.

Did we exceed your expectations?

If Yes, share your valuable feedback on Google